Update 01/02/2014 - Added some early Pics

Raw printed chassis that I designed. Very simply base platform and two tubes to hold the motors.

Personal comments, reivews and suggestions from an I.T./Car/GTD/Home Automation/coder/Local Government kind of guy.

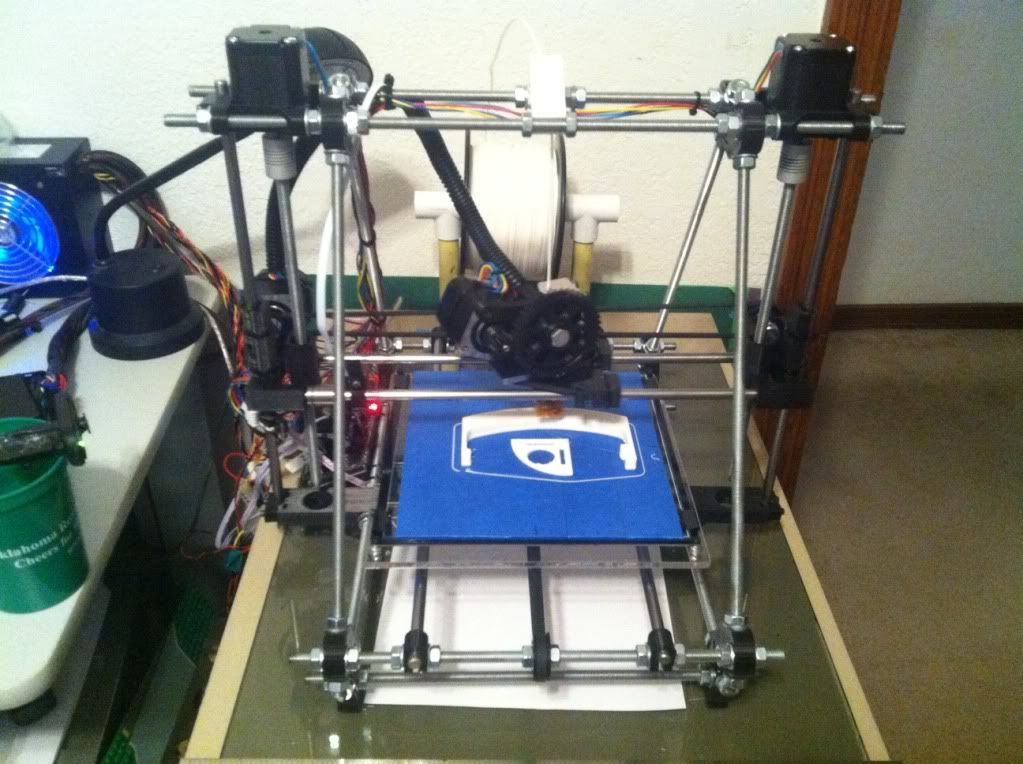

After the little delay in getting filament, it finally arrived from the new vendor. In the mean time I had almost forgotten that I need something to hold the spool so I scrounged around in the garage and found a bunch of leftover PVC T’s from my compressed air piping runs in the garage but had no PVC pipe left over. So I started looking around and found a sacrificial broom whose handle fit nice and snugly into the PVC T’s A few 4.5” cuts later (btw, broom handles are much easier to cut that M8 rod :-/ ) I had a stand that should handle both the larger and smaller rolls of PLA.

After the little delay in getting filament, it finally arrived from the new vendor. In the mean time I had almost forgotten that I need something to hold the spool so I scrounged around in the garage and found a bunch of leftover PVC T’s from my compressed air piping runs in the garage but had no PVC pipe left over. So I started looking around and found a sacrificial broom whose handle fit nice and snugly into the PVC T’s A few 4.5” cuts later (btw, broom handles are much easier to cut that M8 rod :-/ ) I had a stand that should handle both the larger and smaller rolls of PLA. So back to bed leveling and looking for a guide solution for the filament. The bed nut issue was simple, do what everyone tells you to do and put a dab of nail polish on each nut/thread when you’re level. Did that and done. The other issue wasn’t quite so simple. How to keep the 1.75 in the channel. I figured there were a few possible reasons; 1) I didn’t get the clamp bolts tight enough, 2) I didn’t tighten them evenly so it walks out one side, or 3) the hobbed bolt is really for 3mm and it’s just not a sharp enough cut to hold it in the center. So just to make sure and get a clean print, I retightened the bolts trying to get them even but the bolt issue was so easy. To test a guide I cut up a small piece of aluminum, slotted it and servo taped it to the extruder.

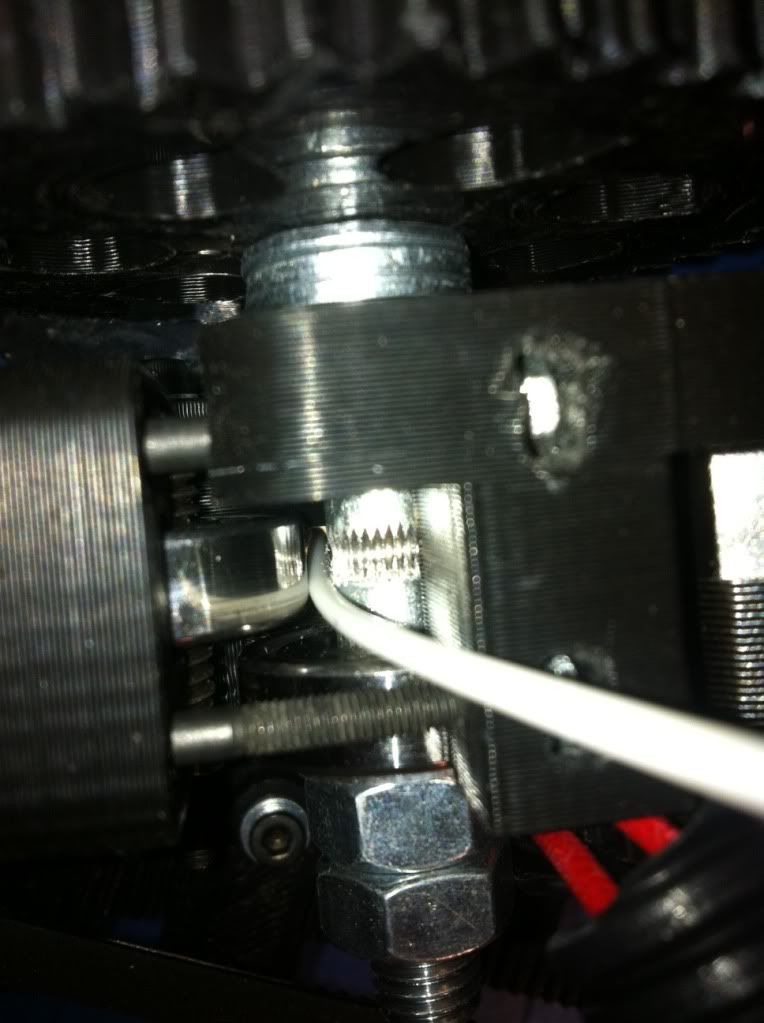

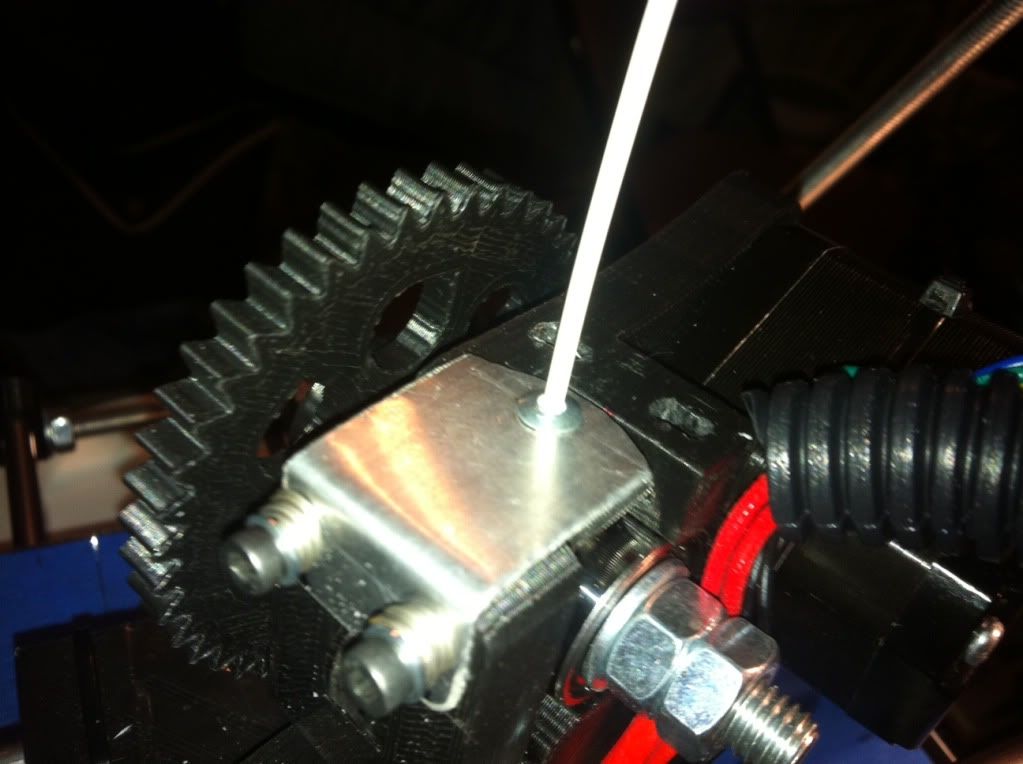

So back to bed leveling and looking for a guide solution for the filament. The bed nut issue was simple, do what everyone tells you to do and put a dab of nail polish on each nut/thread when you’re level. Did that and done. The other issue wasn’t quite so simple. How to keep the 1.75 in the channel. I figured there were a few possible reasons; 1) I didn’t get the clamp bolts tight enough, 2) I didn’t tighten them evenly so it walks out one side, or 3) the hobbed bolt is really for 3mm and it’s just not a sharp enough cut to hold it in the center. So just to make sure and get a clean print, I retightened the bolts trying to get them even but the bolt issue was so easy. To test a guide I cut up a small piece of aluminum, slotted it and servo taped it to the extruder.

Digging around in the garage again I started thinking I need a small tube that can go deep enough into the extruder right down to the hobbed bolt to keep the walking to a minimum. Small tubes were abundant but none had any good mounting options. Then it hit me to try a

Digging around in the garage again I started thinking I need a small tube that can go deep enough into the extruder right down to the hobbed bolt to keep the walking to a minimum. Small tubes were abundant but none had any good mounting options. Then it hit me to try a

Having watched those who have built printers in the public eye like Hoff70, DanM, (others?) and seeing the vast list of options, printers, versions of the same printer, options on top of options for existing printers, and all the other confusing stuff that swirls around the 3D print world, I was quite leery of getting my feet wet, much less diving in headfirst and risk breaking my neck… or pocket book.

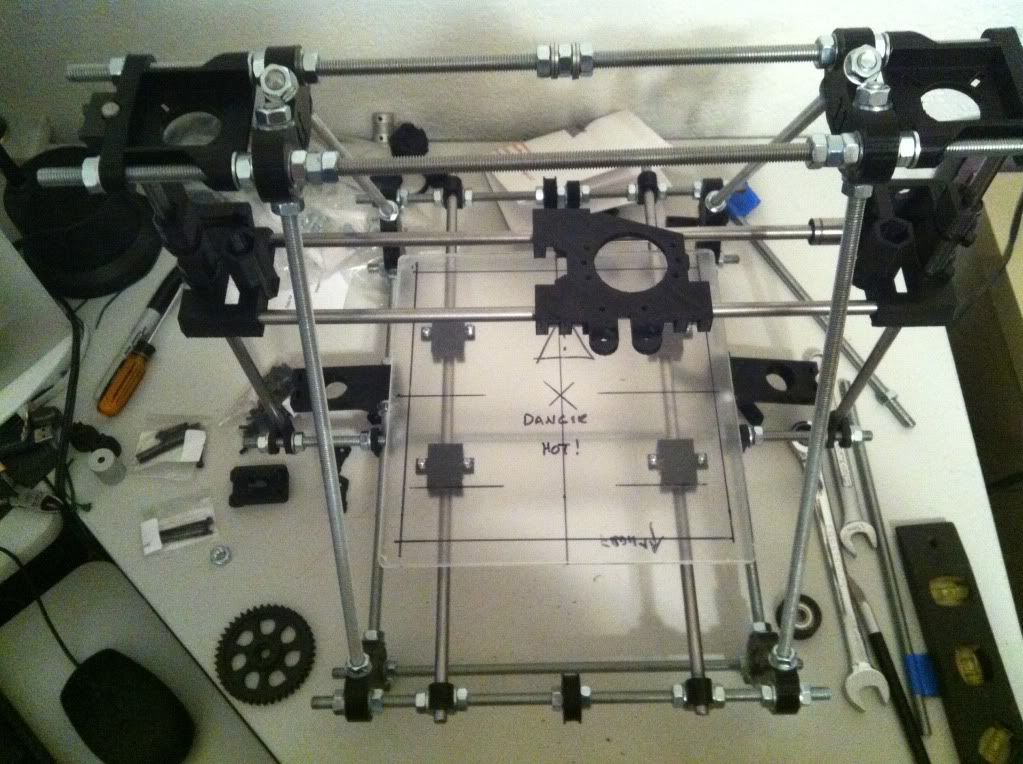

Having watched those who have built printers in the public eye like Hoff70, DanM, (others?) and seeing the vast list of options, printers, versions of the same printer, options on top of options for existing printers, and all the other confusing stuff that swirls around the 3D print world, I was quite leery of getting my feet wet, much less diving in headfirst and risk breaking my neck… or pocket book. So armed with a list and estimated prices I headed online to eBay, MakerFarm, SainSmart and others planning out my purchase route. The first steps are getting the basic frame built so I looked through options for rods, metric hardware, printed parts, and linear bearings. I also ran across some 5mm x 8mm couplers that looked like a better option that printed and picked them up as well as some metal stepper gears and GT2 belts. The rods, printed parts, and hardware arrived I spent an afternoon assembling it all. I chose an un-cut rod kit so quite a bit of time was measuring and cutting threaded and smooth rods to the right lengths. I also polished the smooth rods with some 1000 grit wet sand paper hoping to get things as smooth as possible. Note in the pic above the carriage is on backwards - fixed it right after that pic.

So armed with a list and estimated prices I headed online to eBay, MakerFarm, SainSmart and others planning out my purchase route. The first steps are getting the basic frame built so I looked through options for rods, metric hardware, printed parts, and linear bearings. I also ran across some 5mm x 8mm couplers that looked like a better option that printed and picked them up as well as some metal stepper gears and GT2 belts. The rods, printed parts, and hardware arrived I spent an afternoon assembling it all. I chose an un-cut rod kit so quite a bit of time was measuring and cutting threaded and smooth rods to the right lengths. I also polished the smooth rods with some 1000 grit wet sand paper hoping to get things as smooth as possible. Note in the pic above the carriage is on backwards - fixed it right after that pic. |

| Are You Home Yet? The System Knows... |

|

| Mobile Status Screen for My Home Automation System |

'** GetLatitude.vbsGet Google Latitude Lat/Lon for the user and log to the Log database

'v1.00 - SWN - 10/29/2011

'** Debugging flag - True to see messages

MyDebug = TRUE

'** Your information and location to test against

'** Google Latitude User ID

UserID = "{Your Latitude Code Here}"

'** Location Latitude to test against

LocLat = 35.32

'** Location Longitude to test against

LocLon = -96.92

'** If you are within 1/2 Mile of LocLat/LocLon then If triggers

CheckDistance = .5

'** First get the user (YOU) current location from the Latitude JSON feed

MyLonLat = GetLatitude(UserID)

'** Debug stuff - show it if debugging

If MyDebug then MsgBox "Raw Coords: " & MyLonLat

'** Split out the Lat/Lon from the results

MyCoordsA = SPLIT(MyLonLat)

MyLon = MyCoordsA(0)

MyLat = MyCoordsA(1)

'** Now do a distance check between the points

'** Note this uses another free web API, GeoCoder.us to calc this for us

'** You could build your own dist compare if you wanted... but why if this is there?

'** Distance returned is in Miles so you can convert as desired from there

MyDistance = GetDistance(MyLat, MyLon, LocLat, LocLon)

'** Show distance if debugging

If MyDebug then MsgBox "Distance: " & MyDistance

'** Now take action on the distance check results

'** Obviously you will have to have some session state here so this doesn't fire on every check

'** In my HA system, it sets a Home flag so my code checks if the should be changed and takes action if needed

If MyDistance < CheckDistance then

'** Do something cool because you're close

MsgBox "You are within " & MyDistance & " of your target location."

Else

'** Do something else because you're not

MsgBox "You are OUTSIDE of your target location by " & MyDistance - CheckDistance & " miles."

End If

'** get the Lat/Lon data from your Google Latitude Feed

Function GetLatitude(strUserID)

Set objHttp = CreateObject("Msxml2.ServerXMLHTTP")

objHttp.Open "GET", "http://www.google.com/latitude/apps/badge/api?user=" & strUSERID & "&type=json&callback=parse", False

objHttp.Send

html = objHttp.ResponseText

Lines = Split(html, "[", -1, 1)

Count=UBound(Lines)

MyCoords = lines(2)

MyCoords = LEFT(MyCoords,INSTR(MyCoords,"]") - 1)

GetLatitude = MyCoords

Set objHTTP = nothing 'Release the object

End Function

'** Calc the distance between two lat/lon points and return as MILES

Function GetDistance(Lat1, Lon1, Lat2, Lon2)

Set objHttp = CreateObject("Msxml2.ServerXMLHTTP")

GetLink = "http://geocoder.us/service/distance?lat1=" & Lat1 & "&lat2=" & Lat2 & "&lng1=" & Lon1 & "&lng2=" & Lon2

objHttp.Open "GET", GetLink, False

objHttp.Send

html = objHttp.ResponseText

'** Parse out the information here

StartPos = Instr(html,"=")

EndPos = Instr(html,"mile")

GetDistance = Ltrim(Rtrim(Mid(html,StartPos + 1, EndPos-StartPos-1)))

GetDistance = GetDistance * 1

Set objHttp = Nothing

End Function

I met a man that I hadn't see for a long time the other day. He was a huge influence for me years ago and I had a chance to catch up on life with him. Thirty plus years ago he gave me opportunities as a "twenty-something" that I would be hard pressed to duplicate today for the younger people I know. I can't imagine handing similar projects over to someone that young that we're so important to a company.

I met a man that I hadn't see for a long time the other day. He was a huge influence for me years ago and I had a chance to catch up on life with him. Thirty plus years ago he gave me opportunities as a "twenty-something" that I would be hard pressed to duplicate today for the younger people I know. I can't imagine handing similar projects over to someone that young that we're so important to a company. |

| PDP-11/34 Main CPU |

Technology is a Tool

Technology is a Tool (Just an excerpt from the most recent IT Update at the City of Shawnee I wrote. Nothing earth shattering but quite true IMHO)

Just like the caveman used a club and fire, the modern man and women have tools to do the jobs of the day. The computer, and other technology, are simply that… tools of the current time. Yes, we still use clubs and fire, but just like in the caveman days, the ones what knew and used the tools the most effectively survived yet another day and thrived.

It’s pretty hard to think of any position at the City where a computer type device doesn’t come in to play somehow, somewhere… or won’t be in the near future. Meter readers use handheld devices, janitors use email, offices workers spend a majority of their time on a box, Police have laptops in their cars, Fire has iPads in their hands. Water and Sewer plants run on embedded systems, and Cemetery workers use databases and soon GPS and GIS. Garage mechanics lookup manuals and help online, and soon line workers will be using iPads to see their networks of water and sewer pipes.

So when we hear someone say “I don’t know much about computers” I pause and think: “How do you do your job then?” I know, maybe we’re partial to the whole technology thing since that’s our job to keep it all working, but seriously, how do you do your job the most effective and efficient way if you don’t know the tools you use?

If you’re waiting for someone to show you everything you need to know then you’ll always be behind the learning curve. Just look around a little and you’ll see all kinds of help waiting there for you to be proactive with. On the COS Intranet you’ll see Computer Self Help, INCODE Help and Documents, Global Records information, how to add printers, setup email, and more. And once you are using a piece of software, nearly everything you need to know is often lurking behind that HELP button or menu item. If you say you don’t have time to learn, I challenge you that you don’t have time NOT to learn how to be more effective with the tools of the 21st century… technology and computers.

Just don’t use the club or fire I talked about on the Computer.. that doesn’t help.